Industrial Gearbox Rebuild

A Breakdown Of Our Industrial Gearbox Rebuild Service

1. Arrival and Initial Diagnosis

Upon arrival at one of our Kontrolmek workshops, a gearbox is assigned to one of our expert engineers. This engineer will then prepare for a full diagnostic of the part, investigating any problems listed by the customer, in addition to performing a full visual inspection of all internal & external components.

2. Disassembly

3. Repair & Service

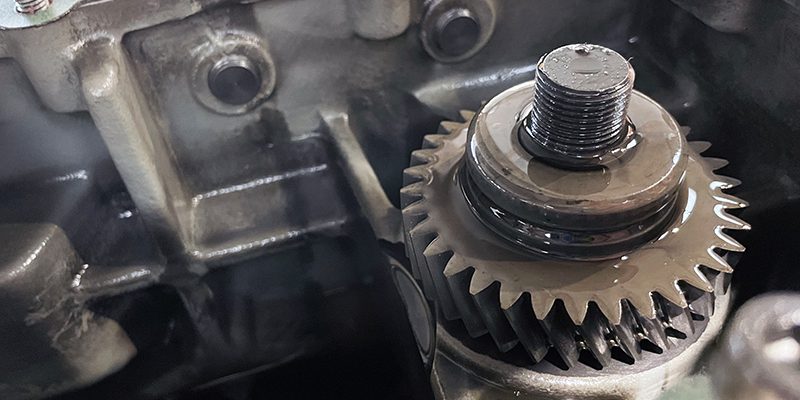

Now that all the disassembled components are cleaned, our expert engineers will inspect each of them and any housing for faults or damage. Examples of problems often identified by our engineers include damage or wear to gear teeth, bearings, and cracks within the gearbox housing. If a Kontrolmek engineer recognises any issues with a certain component they will get to work repairing it.

There are some faults that our engineers are unable to repair, damage to gear teeth being the most common. In these cases, a Kontrolmek engineer would request for a new replica of that component to be made or purchased. In addition to any repairs being made, our engineers will also undertake a service of the gearbox. This full service involves replacing all seals, bearings and oil, as well as respraying all gearbox housing.

4. Reassembly & Testing

Once our engineers have finished all repairs and servicing, the gearbox is then ready to be reassembled. The assembly process is relatively straightforward, our Kontrolmek engineers will fit all repaired and cleaned components back into the gearbox housing. It is incredibly important for the engineer to know where and how each component fits within the gearbox housing to prevent any unnecessary damage.

5. Testing & Return

In this final stage of the repair, our engineers will test the gearbox on a specialised testing rig. This testing ensures that components are correctly fitted within the gearbox and that each is performing its job accurately. During the process, our Kontrolmek engineers will monitor the gearbox for any abnormal noises or vibrations that could indicate a persistent fault. Provided that the engineer is happy with how the rebuilt industrial gearbox is performing, they will then request for it to be packaged and shipped back to the customer.